What are the types of lug butterfly valve?

PUBTIME:2021-08-27 02:21:48

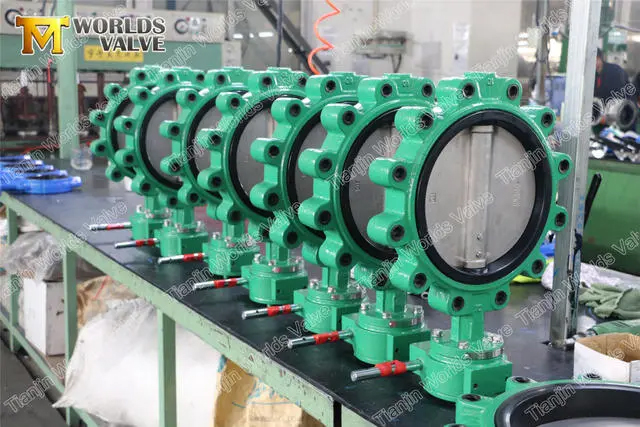

A lug butterfly valve is a type of quarter-turn valve that controls the flow of a product in a pipeline. From pharmaceuticals to manufacturing and food processing, the lug butterfly valve has a variety of applications and can be used to limit solid, liquid, or gas material flow. The lug butterfly valve has threaded lugs outside the butterfly valve body. Two sets of bolts connect pipe flanges to each side of the bolt inserts without nuts. Lug butterfly valves used in dead end service generally have a lower pressure rating. The lug butterfly valves, unlike the wafer butterfly valves, carry the weight of the piping through the valve body.

What are the types of lug butterfly valve?

What is the difference between lug butterfly valve and wafer butterfly valve?

How to choose right lug butterfly valve?

What are the types of lug butterfly valve?

The driving mode of the lug butterfly valve can be manual, worm gear, pneumatic and electric. The connection mode of lug butterfly valve can be flange and butt clamp. The structure of lug butterfly valve can be single eccentric, center line, double eccentric and triple eccentric. The sealing structure of lug butterfly valve can be soft seal and hard sealed.

Electric lug butterfly valve relies on the power drive of the electric actuator to control the opening and closing of the valve. The electric lug butterfly valve itself has no flange, and the valve body thickness is relatively thin. A set of bolts is directly passed through the bolt hole, and the electric lug butterfly valve is clamped between the flanges at both ends of the pipeline, and then connected with bolts. Therefore, electric lug butterfly valve is especially suitable for working conditions where the site space is limited and the pipeline distance is relatively short. Due to the fact that the bolts will expand and cause leakage when the temperature is high, the lug electric butterfly valve is generally not recommended to be used in high temperature conditions.

The pneumatic lug butterfly valve adopts the method of wafer clamping. The butterfly valve is clamped between the flanges at both ends of the pipeline, and then fixed with a set of bolts. The valve body of the pneumatic lug butterfly valve is small in size and relatively thin in thickness. Pneumatic lug butterfly valve is especially suitable for occasions where the distance between the two ends of the pipeline is short or the space is limited. Pneumatic lug butterfly valves are divided into soft seals and metal seals according to different density structures. The soft seal butterfly valve is a centerline structure, which has the advantages of anti-corrosion and zero leakage, while the hard seal butterfly valve is a triple eccentric type, which has the advantages of wear-resistance and long life.

What is the difference between lug butterfly valve and wafer butterfly valve?

Butterfly valves are usually grouped into two types, that are, lug butterfly valve and wafer butterfly valve. These mechanical components are not interchangeable and have distinct advantages and applications.

Lug butterfly valves are usually composed of metal such as ductile iron or steel. One of the features of lug butterfly valve is that threaded tapped lugs positioned on the valve flanges for bolt connections. Lug butterfly valves are suitable for end-of-line service but a blind flange is always recommended. Lug butterfly valves are manufactured to be compatible with either pneumatic or electric actuation. Disc and seat material should be determined based on application and flow media.

Most wafer butterfly valves are engineered with four holes that align with the connected pipeline. The wafer butterfly valve is designed to clamp between two flanges in your pipe work. Most wafer butterfly valves fit the majority of flange standards. The rubber or EPDM valve seat creates an exceptionally strong seal between the wafer butterfly valve and flange connection. Wafer butterfly valves cannot be used as pipe ends or end-of-line service. The entire line must be shut down if either side of the wafer butterfly valve requires maintenance.

How to choose right lug butterfly valve?

Butterfly valves are comprised of four main components, that are, the body, stem, disc and seat. The body can be manufactured in either the lug or wafer style. The difference between the two is in the mounting design.

The lug of lug butterfly valve can be considerably larger as it incorporates threaded alignment inserts, allowing it to be installed directly into a system with bolts. This also provides the option to use the lug butterfly valve in a dead-end service.

The stem in a lug butterfly valve holds the disc in its proper position and provides its rotational direction when actuated. Successful control of flow is attributed to the disc and seat combination.

Proper seat and disc material choices are essential when choosing a lug butterfly valve for an application. Selecting the wrong lug butterfly valve can damage the entire operation. It is important to know the size, temperature, application, media, pressure and speed to make a proper selection. With this, lug butterfly valve manufacturers can help identify the optimal valve type for the application.

Learn more something about lug butterfly valve can know the types of lug butterfly valve and how to choose lug butterfly valve. In the process of butterfly valve development, a number of very powerful companies have emerged, such as Tianjin Worlds Valve Co., Ltd. Our company knows how to innovate while developing, and will also go out in the process of introducing lug butterfly valve.

Pre:None

Next:UNIVERSAL WAFER TYPE BUTTERFLY VALVE

No.25,Fuhui Road,Beizhakou Industrial Zone,Jinnan District ,Tianjin,China

Copyright 2021 TIANJIN WORLDS VALVE CO.,LTD. All Rights Reserved

Mobile+86-22-28522277